LEDs have replaced nearly all different kinds of traditional light sources. The reason is quite simple: LED illumination fulfills customer requirements in terms of efficiency, size and longevity. Nevertheless, with LED new topics arise for optic manufacturers. LED optics require special handling of lighting mixing and diffusion for smooother light distributions and a better color mixing. One approach, especially when used with refractive optics, is an adapted surface treatment which can be realized both as rough or periodic structures. We offer both methods to our customers:

Rough surfaces can be realized with sandblasting or electrical discharge machining. Both the tools for glass production and the final glass part can be treated.

For better light control we also offer surface structures build up by regular or quasi-regular arrangements of spherical scatter elements.

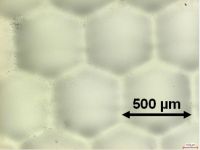

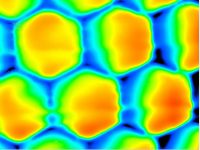

For hot-forming, where glass is pressed from the liquid phase, we can realize gratings with lattice constants down to 500 μm. Typical surface deviations are in the range of 5 μm, which allows for good light control.

Figure 1: Directly pressed micro structure: hexogonal grating with lattice constant of 500 μm. Microscope image of the surface. False color diagram of surface profile.

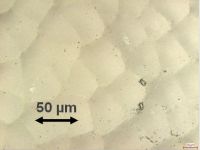

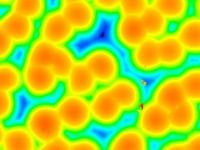

We also implemented a post processing, where surface structures are imprinted onto the glass surface. With this technology we are able to replicate lattice constants below 50 μm and surface deviations of only 1 μm.

Figure 2: Imprinted micro structure: semi random arrangement with average distance of 50 μm. Microscope image of the surface. False color of surface profile.

Surface structuring fetches plenty of interest in the market as there are many applications: lenses with smooth light distributions, diffusion disks for LED/laser and light guides with superior color mixing.

We use cookies. Some of them are necessary to make the website usable. Others help us display information that is relevant and engaging to you. As data protection is important to us, we ask you to decide on the scope of use. You can either accept all cookies or choose your individual settings. You can withdraw your consent at any time by reopening this tool. Thanks and enjoy our website!

This is an overview of all cookies used on this website. Please make your individual settings. You can adapt them at any time by using the "Cookie settings" link in the footer of this website.

These cookies are essential to the operation of the website, e.g. by saving your cookie settings.

| Name | alto. Cookie |

|---|---|

| Provider | Provider |

| Purpose | Saves the visitor's settings |

| Identifier | alto-cookie |

| Validity | 1 year |

Tools collecting usage data anonymoulsy, giving insights into how to improve our services for you.

| Accept | |

|---|---|

| Name | Google Analytics |

| Provider | Google LLC |

| Purpose | Google cookie for website analyses. Creates statistical data on website usage. |

| Privacy | https://policies.google.com/privacy |

| Identifier | _ga,_gat,_gid |

| Validity | 2 years |

Tools enhancing the browsing exerience, e.g. maps or videos.

| Accept | |

|---|---|

| Name | YouTube |

| Provider | YouTube, LLC |

| Purpose | Used to unlock Youtube contents. |

| Privacy | https://policies.google.com/privacy |

| Identifier | yt-remote-fast-check-period, yt-remote-session-app, yt-remote-session-name |

| Validity | Session |

| Accept | |

|---|---|

| Name | Google Maps |

| Provider | Google LLC |

| Purpose | Used to unlock Google Maps contents. |

| Privacy | https://policies.google.com/privacy |

| Identifier | NID |

| Validity | 2 Years |

| Accept | |

|---|---|

| Name | Vimeo |

| Provider | Vimeo, LLC |

| Purpose | Used to unlock Vimeo contents. |

| Privacy | https://vimeo.com/privacy |

| Identifier | vuid |

| Validity | 2 Years |