###USER_salutation###,

Six busy months of 2018 are now already behind us. Auer's presence on a number of exhibitions and conferences starting with the Photonics West in San Francisco, LED Next Stage exhibition in Tokyo, L&B and Optatech in Frankfurt, and the Get Show in Guangzhou gave overwhelming feedback and motivation.

Thank you to all who spent a visit to our booths! This is our inspiration for new, innovative products and technologies. Let's work on your tomorrow's products.

Enjoy the summer time, your

Auer Lighting Sales Team

We are happy to present our latest newsletter to you! If you don't want to receive future editions, you may unsubscribe at any time. Please find the link at the end of this email.

For more information about Auer Lighting click here to visit our website.

Whenever there is a low demanding environment, parts made from polymer materials (aka “plastics”) are considered for their low weight and freedom in design. They are used for automotive, general lighting and medical applications enabling energy savings and cost effective production. Often an additional coating is required to bring plastics on a good performance level. This makes a special cleaning of the surface, a precise handling and a superior deposition process necessary. Only then the result allows for excellent optical performance, adhesion and durability – a perfect match for our capabilities.

Auer Lighting has been producing innovative coating solutions for professional applications for decades. Based on that in-depth expertise, we offer you our competencies also for the coating on plastics. Most polymer materials cannot resist the typical 200 °C temperatures used for the coating of glass, so our engineers have designed a low temperature deposition process, working at temperatures lower than 80 °C. By means of plasma impulse chemical vapor deposition (PICVD) and MicroDyn sputtering we can redefine plastics with an anti-reflex or dichroitic surface. Our magnetron sputtering also allows for the deposition of metal films on a plastic substrate and can be used for decorative and optical reflectivity.

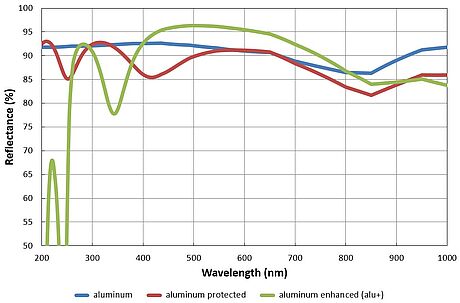

In case of optical requirements, very often those metal films are used to improve the performance of the product. Aluminum is a good partner for highly reflective optical surfaces in the visible spectrum with reflectance up to R = 90%.

However, a sputtered aluminum thin film is very fragile without a protective overcoat made of a dielectric material. SiO2 protected aluminum is our most popular mirror coating in the visible and near-infrared regions. The SiO2 top coat provides an abrasion-resistant surface, high durability and an oxidation barrier while maintaining the performance of the bare aluminum mirror. Furthermore, a special top coat can be designed to enhance the visible reflection (up to 95%, see diagram above) even further. Its name: “alu+”. The so-called enhanced aluminum meets the highest quality requirements for reflective surfaces. The overcoating is a unique, highly durable multilayer dielectric film.

Download our flyer and contact us to learn more.

Aluminium, the metal used for our superior "alu+" coatings, makes up nearly 8% of the Earth's crust (by mass).

Auer Lighting – 70 years of passion for glass

We use cookies. Some of them are necessary to make the website usable. Others help us display information that is relevant and engaging to you. As data protection is important to us, we ask you to decide on the scope of use. You can either accept all cookies or choose your individual settings. Thanks and enjoy our website!

This is an overview of all cookies used on this website. Please make your individual settings. You can adapt them at any time by using the "Cookie settings" link in the footer of this website.

These cookies are essential to the operation of the website, e.g. by saving your cookie settings.

| Name | alto. Cookie |

|---|---|

| Provider | Provider |

| Purpose | Saves the visitor's settings |

| Identifier | alto-cookie |

| Validity | 1 year |

Tools collecting usage data anonymoulsy, giving insights into how to improve our services for you.

| Accept | |

|---|---|

| Name | Google Analytics |

| Provider | Google LLC |

| Purpose | Google cookie for website analyses. Creates statistical data on website usage. |

| Privacy | https://policies.google.com/privacy |

| Identifier | _ga,_gat,_gid |

| Validity | 2 years |

Tools enhancing the browsing exerience, e.g. maps or videos.

| Accept | |

|---|---|

| Name | YouTube |

| Provider | YouTube, LLC |

| Purpose | Used to unlock Youtube contents. |

| Privacy | https://policies.google.com/privacy |

| Identifier | yt-remote-fast-check-period, yt-remote-session-app, yt-remote-session-name |

| Validity | Session |

| Accept | |

|---|---|

| Name | Google Maps |

| Provider | Google LLC |

| Purpose | Used to unlock Google Maps contents. |

| Privacy | https://policies.google.com/privacy |

| Identifier | NID |

| Validity | 2 Years |

| Accept | |

|---|---|

| Name | Vimeo |

| Provider | Vimeo, LLC |

| Purpose | Used to unlock Vimeo contents. |

| Privacy | https://vimeo.com/privacy |

| Identifier | vuid |

| Validity | 2 Years |