MAXOS®

Safety Sight and Level Gauge Glasses

Bending strength is determined by the surface compressive stress and the inherent resistance of the glass. The inherent resistance is heavily dependent upon the surface quality.

For safety reasons, the stress to the glasses caused by internal forces, thermal stress and vessel pressure have to be totally absorbed by the surface compressive stress so that a tensile stress of the glass surface is prevented.

| Application conditions | Maximum permissible pressure | Maximum permissible temperature | ||

|---|---|---|---|---|

| bar | psi | °C | °F | |

| Saturated steam or hot water in direct contact with reflex or transparent sight glasses | 35 | 500 | 243 | 470 |

| Saturated steam or hot water in contact with transparent sight glasses protected with mica | 103 | 1,500 | 320 | 608 |

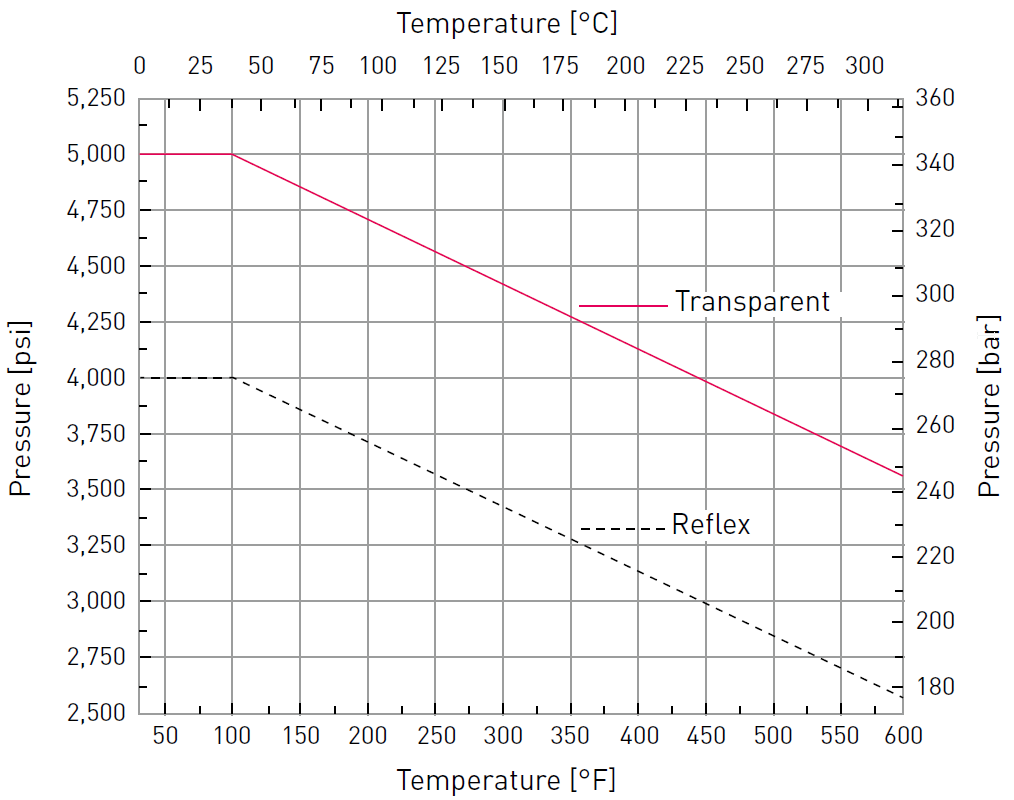

| Non-corrosive, non-steam service and no technically significant glass attack, with reflex or transparent glasses | 280 | 4,000 | 38 | 100 |

| Transparent sight glasses in contact with medias with no technically significant glass attack | 345 | 5,000 | 38 | 100 |

| High pressure transparent sight glasses in special gauges | 414 | 6,000 | 38 | 100 |

| Thermal shock resistance | Δ T 230 °C |

| Max. permissible temperature | 300 °C (572 °F) |

| Protected with mica | 320 °C (608 °F) |

| Standard level gauge glasses | |

|---|---|

| ≥ 90 N/mm2 | 13,000 psi |

| Average 100 N/mm2 | 14,500 psi |

| High pressure level gauge glasses | |

|---|---|

| ≥ 100 N/mm2 | 14,500 psi |

| Average 110 N/mm2 | 16,000 psi |

| Standard level gauge glasses | |

|---|---|

| ≤ 0.13 mm | 0.005 inches |

| High pressure level gauge glasses | |

|---|---|

| ≤ 0.05 mm | 0.002 inches |

| Standard level gauge glasses | |

|---|---|

| ≥ 150 N/mm2 | 21,000 psi |

| Average 170 N/mm2 | 25,000 psi |

| High pressure level gauge glasses | |

|---|---|

| ≥ 180 N/mm2 | 26,000 psi |

| Average 200 N/mm2 | 29,000 psi |

We use cookies. Some of them are necessary to make the website usable. Others help us display information that is relevant and engaging to you. As data protection is important to us, we ask you to decide on the scope of use. You can either accept all cookies or choose your individual settings. You can withdraw your consent at any time by reopening this tool. Thanks and enjoy our website!

This is an overview of all cookies used on this website. Please make your individual settings. You can adapt them at any time by using the "Cookie settings" link in the footer of this website.

These cookies are essential to the operation of the website, e.g. by saving your cookie settings.

| Name | alto. Cookie |

|---|---|

| Provider | Provider |

| Purpose | Saves the visitor's settings |

| Identifier | alto-cookie |

| Validity | 1 year |

Tools collecting usage data anonymoulsy, giving insights into how to improve our services for you.

| Accept | |

|---|---|

| Name | Google Analytics |

| Provider | Google LLC |

| Purpose | Google cookie for website analyses. Creates statistical data on website usage. |

| Privacy | https://policies.google.com/privacy |

| Identifier | _ga,_gat,_gid |

| Validity | 2 years |

Tools enhancing the browsing exerience, e.g. maps or videos.

| Accept | |

|---|---|

| Name | YouTube |

| Provider | YouTube, LLC |

| Purpose | Used to unlock Youtube contents. |

| Privacy | https://policies.google.com/privacy |

| Identifier | yt-remote-fast-check-period, yt-remote-session-app, yt-remote-session-name |

| Validity | Session |

| Accept | |

|---|---|

| Name | Google Maps |

| Provider | Google LLC |

| Purpose | Used to unlock Google Maps contents. |

| Privacy | https://policies.google.com/privacy |

| Identifier | NID |

| Validity | 2 Years |

| Accept | |

|---|---|

| Name | Vimeo |

| Provider | Vimeo, LLC |

| Purpose | Used to unlock Vimeo contents. |

| Privacy | https://vimeo.com/privacy |

| Identifier | vuid |

| Validity | 2 Years |