MAXOS®

安全視認ガラス及びレベルゲージガラス

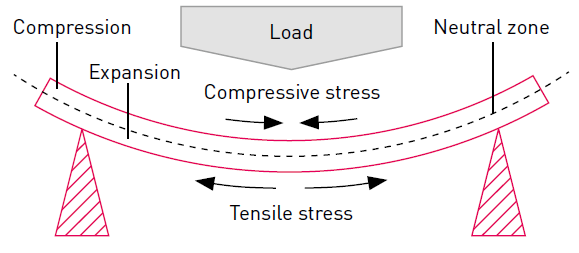

The specially developed SUPRAX® 8488 borosilicate glass used for the MAXOS® sight glasses guarantees a superior chemical resistance. The low expansion of the glass combined with thermal prestressing creates a high resistance to sudden temperatures changes.

| Technical properties | |||

|---|---|---|---|

| Coefficient of expansion α 20 °C/300 °C | 4.1 x 10–6K–1 | ||

| Max. operating temperature | 300 °C | 572 °F | |

| Thermal shock resistance as per ISO 718 | ΔT 230 °C | ||

| Transformation temperature | 545 °C | ||

| Glass temperature for the viscosities dPas (Poise) | 1013.0 107.6 104.0 | 560 °C 800 °C 1,210 °C | 1,040 °F 1,472 °F 2,210 °F |

| Density at 25 °C | 2.3 g/cm3 | ||

| Modulus of elasticity | 67 x 103 N/mm2 | ||

| Poisson‘s ratio μ | 0.20 | ||

| Thermal conductivity λ at 90 °C | 1.2 W/(m·K) | ||

| Refractive index nd (λ = 587.6 nm) | 1.482 | ||

| Photoelastic parameter K | 3.2 x 10–6 mm2/N | ||

SUPRAX® - a registered trademark of SCHOTT AG

It depends on the proportion: The high amount of silicon dioxide (SiO2) and boric acid (B2O3) characterizes this type as a glass former. The proportion of boric acid influences the glass properties in a specific way: We use a proportion of only 11.5 %. This makes it more stable in comparison to glasses with an even higher boric acid content. In addition, the embedding in the structural network ensures extremely high chemical resistance.

The homogeneous distribution of the thermal prestressing ensures increased breaking strength.

| Chemical characteristics | Hydrolytic resistance | Acid resistance | Alkali resistance |

|---|---|---|---|

| Test acc. to | DIN ISO 720 | DIN ISO 1776 | DIN ISO 695 |

| Max. abrasion acc. to DIN ISO | 0.1 | <100 μg Na2O/dm2 | >75–175 mg/dm2 |

| MAXOS® max. abrasion | 0.050 | <60 μg Na2O/dm2 | >100 mg/dm2 |

| MAXOS® | HGA 1 | – | Class A2 |

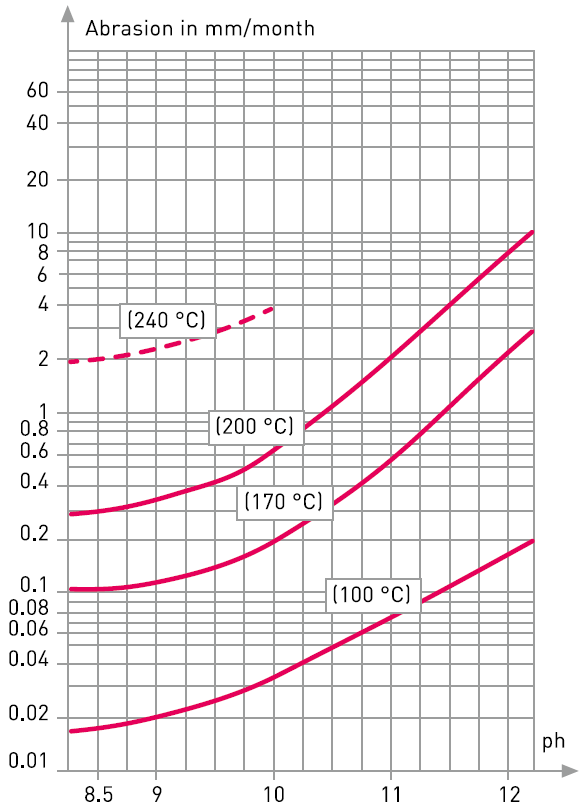

Abrasion of MAXOS® glass in aqueous phase at different temperatures as a function of the ph-value.

We use cookies. Some of them are necessary to make the website usable. Others help us display information that is relevant and engaging to you. As data protection is important to us, we ask you to decide on the scope of use. You can either accept all cookies or choose your individual settings. You can withdraw your consent at any time by reopening this tool. Thanks and enjoy our website!

This is an overview of all cookies used on this website. Please make your individual settings. You can adapt them at any time by using the "Cookie settings" link in the footer of this website.

These cookies are essential to the operation of the website, e.g. by saving your cookie settings.

| Name | alto. Cookie |

|---|---|

| Provider | Provider |

| Purpose | Saves the visitor's settings |

| Identifier | alto-cookie |

| Validity | 1 year |

Tools collecting usage data anonymoulsy, giving insights into how to improve our services for you.

| Accept | |

|---|---|

| Name | Google Analytics |

| Provider | Google LLC |

| Purpose | Google cookie for website analyses. Creates statistical data on website usage. |

| Privacy | https://policies.google.com/privacy |

| Identifier | _ga,_gat,_gid |

| Validity | 2 years |

Tools enhancing the browsing exerience, e.g. maps or videos.

| Accept | |

|---|---|

| Name | YouTube |

| Provider | YouTube, LLC |

| Purpose | Used to unlock Youtube contents. |

| Privacy | https://policies.google.com/privacy |

| Identifier | yt-remote-fast-check-period, yt-remote-session-app, yt-remote-session-name |

| Validity | Session |

| Accept | |

|---|---|

| Name | Google Maps |

| Provider | Google LLC |

| Purpose | Used to unlock Google Maps contents. |

| Privacy | https://policies.google.com/privacy |

| Identifier | NID |

| Validity | 2 Years |

| Accept | |

|---|---|

| Name | Vimeo |

| Provider | Vimeo, LLC |

| Purpose | Used to unlock Vimeo contents. |

| Privacy | https://vimeo.com/privacy |

| Identifier | vuid |

| Validity | 2 Years |